When it comes to programming, it’s important that all data and information is streamlined into something coherent. If things get messy in this arena, then computers will struggle to read or make sense of any of the commands and instructions that come their way. Instead of clear functions, they’re met with sheer noise that’s contradictory and unusable.

However, the modular PLC can help the core unit here and compliment it’s processes well. Of course, first it’s worth asking; what is a modular PLC?

Table of Contents

How does a module PLC Work?

Before the module PLC comes into effect, the base module must be considered first.

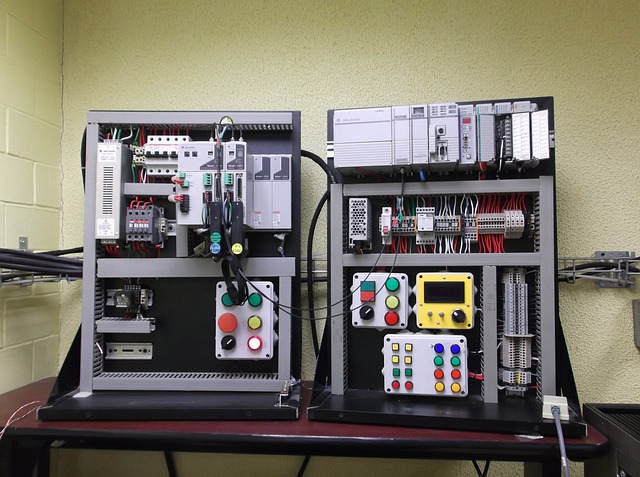

The base module is comprised of a power supply unit (which will knock down your standard 240 voltage to 5 or 12 volts, depending on what the system runs on), and a central processing unit. The modular PLC is attached to the base module without affecting that voltage, and generally acts as an extra arm for the base module to work with, so to speak.

The PLC uses automated systems from an input source and channels a pre-programmed output. Generally speaking, they just trigger switches, whether that’s one isolated switch or multiple buttons that have to be activated in certain sequences. In its purest form, it’s a series of links that communicate with one another for automation to occur.

How can a Modular PLC be Used?

A modular PLC is predominantly used in business to carry out pre-set, automated functions. They’re extensions to the core unit, adding roles that don’t reprogram, but slot another action into the system. For example, for the rail industry they can trigger automatic gates and signalling systems, keeping the flow of trains moving swiftly. It’s automation that makes businesses function with more fluidity, thereby boosting efficiency.

It’s also evenly distributing key corporate information across a digital network. You can have real-time access to your data and assets, protect said information, and do all of this while creating speedier information storage and business functionality. After all, this certainly beats traipsing across office floors and manually performing every task. In the end, the modular PLC maximises efficiency for all businesses looking to dabble in automation pursuits.

Reliable Backup

A base module carries out automated tasks that are governed from a combination of core functions. However, it’s important that the base module isn’t overstretched, or it can succumb to cluttered and confusing programming. If it’s given too much to do, it not only struggles to keep all the automation programming reigned in and under control, but also takes on too much responsibility in a business sense too.

Of course, the problem with a single unit is that if anything goes wrong, you’ve got no backup. You’ve then lost complete functionality of whatever you’re doing or whatever system you’re responsible for. However, if you have other modular PLC’s in there to breakup all the processes, then you don’t lose all your functions if one module goes down. If something goes wrong with a module, one can simply take it out and replace it with another without compromising everything, thereby slashing maintenance costs too.