Companies, in whatever industry they belong to, are now facing a lot of competition. The continuous improvement of technology also implies the challenge to meet new techniques, rise to better standards, and overall provide higher quality and better-made products and services to clients.

The construction industry is not an exemption. What was done by hands many years back, can now be done faster and more efficiently by employing the latest machines. Particularly in the production and fabrication process, factories have seen a change in the scenario.

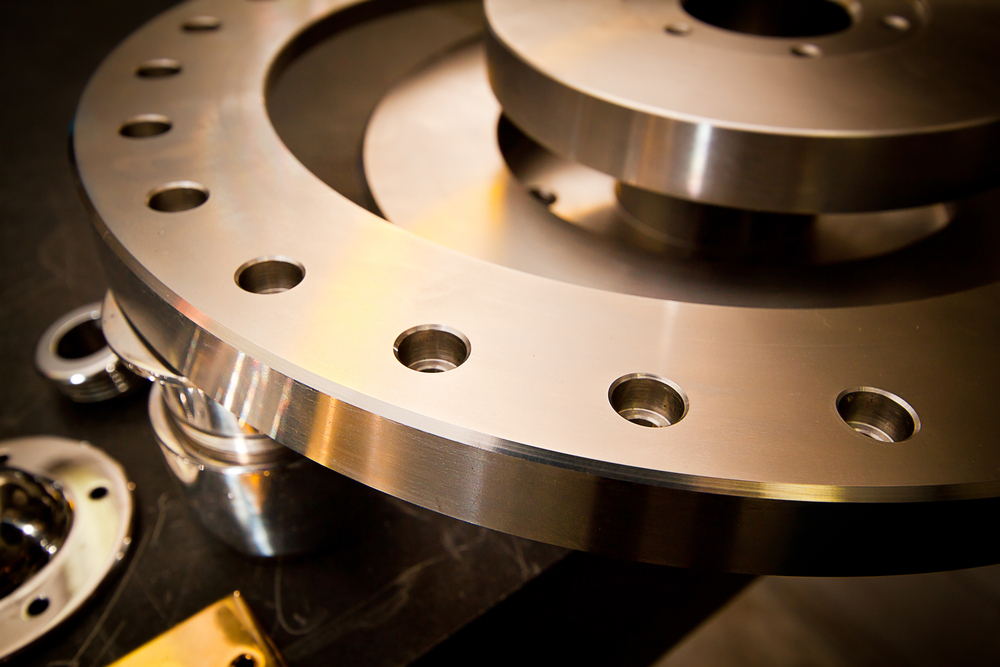

Fabrication refers to the process of cutting and forming shapes, as in this case, through the use of metal. Through technological advancements, the concept of custom metal machining came into play. This creates outcomes that have a better appearance, for an even possibly lower price and faster method.

That said, learn more about custom metal machining and what it can do for your company by reading about it below.

Table of Contents

What Is Custom Metal Machining?

Custom metal machining refers to the process of bending, assembling, cutting, and shaping metal to manufacture the product that meets the needs of the client. You only need to specify the proper dimensions, and then the machine does all the work. Accurately, at that, too.

The products coming up from companies that offer custom metal machining, such as Prototech Asia, are usually used for house and building construction. For instance, stairs that are intricately designed. These can also include products that are further needed for the manufacturing of other equipment.

What Are The Types Of Processes Involved In Custom Metal Machining?

The fabrication of metal has a wide variety of manufacturing process options. This enables industries and clients to have a leeway for customization – to meet their specific needs.

Some of the fabrication processes that are commonly involved in custom metal machining include:

- Welding. This refers to the process of joining two or more workpieces to form a single product. This is achieved through the application of heat or pressure.

- Cutting. This is the process of removing excess metal from an existing piece to create the desired shape.

- Forming. This refers to the process of creating or coming up with the final form of the metal product.

What Are The Steps Involved In Custom Metal Machining?

The process involved in custom metal machining can be a complicated one to understand, especially when you don’t have any knowledge about metals and its corresponding procedures.

To summarize it, however, in a more straightforward way, these are the necessary steps in custom metal machining:

- Have a design of the metal product you wish to be created. Then, present it to the metal fabrication shop.

- Metal is then shaped into the custom design you have, either through cutting, forming, or any of the other processes involved in custom metal machining.

- The metal product is then given its final shape and finish.

What Are The Benefits Of Custom Metal Machining?

Custom metal machining brings with it a host of benefits for companies.

A note to remember, however, is that like any other process, the result is also highly dependent on the family and grade of metal that’s going to be used. Generally, the common types of metals used in industries include nickel, steel, magnesium, iron, copper, and aluminum.

Through the use of these metals, the following advantages are achieved across industries:

- Higher heat resistance. To come up with the desired shape and size, plastics and metals, alike, are placed under a lot of heat.

With metals, however, there’s higher heat resistance. This means that under elevated temperatures of whatever process is next to custom metal machining, the product doesn’t degrade.

- Higher-strength. The end products of custom metal machining are stronger and harder. This means that their level of concentration is heightened. If your company is the manufacturer, you get to present products of better quality to your clients.

Because of this higher strength, naturally, it also means that the finished products are more durable; its quality lasts longer in the hands of the consumers. Generally, these finished products also come in with a better warranty. Though, maintenance and regular replacements of these metal products aren’t going to be as frequent.

- Versatile. Understandably, custom metal machining offers a higher level of versatility to industries. Whatever the custom design is desired by the client, you can achieve this with little to no limits. A wide range of designs can be catered to, from simpler ones, and even to the most complex of all ideas.

In today’s time, customization is one of the highest demands of customers. Clients are always looking for something that others don’t have, yet. When businesses aren’t able to meet this demand, you’ll have customers walking out of your doors.

Additionally, when your company can offer customization through the process of custom metal machining, you’re able to open your doors to a broader range of markets. This means that your profit-earning potential increases as well.

- Creates products that are easier to transport. Because of the more specific and better-defined techniques in custom metal machining, no excess metal products are adhering to the finished product. This means that the result your company creates are relatively lighter products, compared with those that didn’t pass through this machine. Thus, it becomes easier to transport finished products.

As to marketability, this ease of transportation also opens up a wide range of markets for your company. You don’t have to restrict yourself only to clients that are nearby. As you can now better transport your products, your company can now cater to the fabrication needs of more clients living far away from your base. This increases the competitiveness and the marketability of your company, which will also increase profit.

- Cost-effective. Businesses are always on the hunt for the best ways to offer cheaper rates to their clients without sacrificing quality and earning potential. Creating metal products through custom metal machining is also one of the most cost-effective means to do so.

There’s lesser manual labor involved, so it cuts down on this expense. Plus, production is also faster. Hence, these products don’t stay as long anymore in your plant before it reaches the hands of paying clients.

The ROI (return of investment) for these metal products are higher because they don’t need to be regularly replaced. For instance, if a business uses stainless steel utensils, this can last them for many years before new ones need to be bought. Hence, because the products are cheaper, not only is it more cost-effective up front but, in the long run, it’s also more friendly to the pockets of the consumers.

- Resistance is improved. Resistance here not only refers to heat resistance but also that brought about by different weather conditions, such as heat and moisture. The products created through custom metal machining are so refined that they have a higher resistance to whatever weather conditions it’ll be exposed to.

Custom metal machining ensures better malleability of the metal. This means that the metals have an increased capacity to be formed and shaped into something else without breaking. As this is guaranteed from start to finish, by the time the finished product is done, the quality and resistance are already of a superior standard.

- Environmentally-safe. Another one of the standards that businesses, like yours, must meet today is the need to adhere to environmentalism. The majority of clients are now looking for products that are safe for the environment. Products created from custom metal machining reach this standard since it’s a sustainable solution to plastic.

Additionally, metal products also have a low carbon effect and have a more extensive capacity for recycling. When these metal products are no longer of use to the consumers, the metals can further be processed again through custom metal machining to other metal products.

- Reduced production time. Apart from the ability to create customized products, custom metal machining also meets the demands of customers to have finished products, fast. Many customers don’t like to wait for long before their orders get finished. With a manual process, this demand is tough to achieve.

With custom metal machining, there’s a significant reduction in the production time. For instance, less manual work is involved since everything – the shaping and cutting – is done by the machine. Once all the specifications are entered into the machine, it does the work for you. Also, there’s no more need to find the right machine parts.

- Higher accuracy. Another one of the essential advantages that custom metal machining can bring to your company is the fact that it offers higher accuracy as to its finished products. Because less manual work is involved, human error is reduced.

As long as the right specifications are entered in the machine, this can be achieved with very little to no errors at all.

What Are The Different Types Of Metals Used?

Now, it’s also imperative to discuss the different types of metals that are commonly used in custom metal machining. When these metal products go through this process, they each bring about their advantages for the manufacturer (in this case, your company) as well.

Here are some of the common types of metals used:

- Carbon steel. This type of metal is one of the best options to go for when clients need products that are heavy and requires a lot of metal. Carbon steel is mostly used for industries relating to harsh conditions, such as structural applications in construction, tanks, and ducts.

- Stainless steel. This type of metal has high chromium content. When going through the rigorous process of custom metal machining, stainless steel doesn’t easily rust or corrode. While it’s going to cost more than carbon steel, stainless steel is highly in demand in many industries, such as those products that’ll come into contact with food.

- Aluminum. This is an alternative type of metal to stainless steel. Because of its non-corrosive properties, it’s also popular for clients in the food or medical industry. It’s also highly in demand in the aerospace technology.

- Copper. This is a native type of metal. This means that it’s one of the metal types to be used in custom metal machining that’s in its purest state.

Copper has excellent antibacterial properties. Hence, it’s an attractive option for pots, pans, bathtubs, and sinks. Copper is also one of the easiest metals to use for custom metal machining purposes.

What Are The Disadvantages Of Custom Metal Machining?

As the advantages are already discussed, it’s also essential to run through the disadvantages it can bring to your company. That way, before you make a final decision, your company has already gone through a well-informed choice. Even more importantly, an awareness of the disadvantages will also help you make the necessary precautionary measures to ensure that these disadvantages won’t be as deeply felt as it should be.

Here’s one of the most prompting disadvantages of custom metal machining:

- The start-up cost is high. This disadvantage is a given and accepted fact for all companies looking to make a significant change in their production process. Because custom metal machining inherently means that your company is going to switch to more mechanized processes, the investment cost is going to be high since the necessary machines have to be purchased. Then, there’s also the training and the operating costs involved.

However, these costs will be worth it in the long run; the benefits that it brings to your company outweigh this cost. Thereby, this means that your company will also be reaping the benefits of the investment that you’ve placed into custom metal machining. Thus, it’s not an investment that’s only going to turn lemon.

Conclusion

Many years back, clients were already contented with off-the-shelf metal products. But, today, more and more clients are demanding more. They want the best quality, the most refined products, and they want to own metal products that other people don’t have.

Custom metal machining enables your company to achieve this competitive advantage. The basis here is solely reliant on the design and the needs of your client. Hence, your company can give your clients what they demand, and so much more.