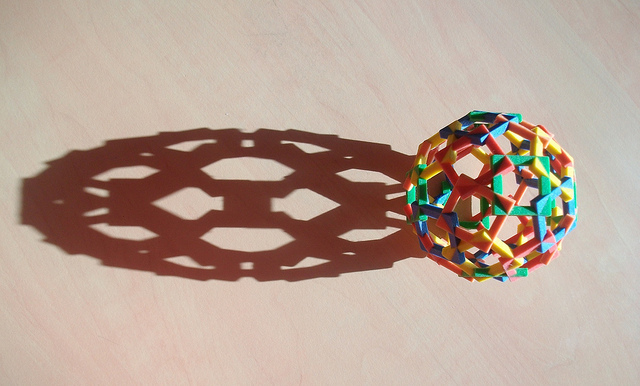

Credit: fdecomite

The year-over-year growth forecasts projected with the advent of 3D printing technology are just starting to come to fruition. This new technology is expected to render many current manufacturing processes obsolete in a new economy where everything will be customizable and consumers will be able to obtain their purchases immediately. With applications ranging from consumer purchasing of downloadable files to custom-designed medical devices, the 3D printer is beginning to make its impact on the manufacturing industry

Table of Contents

Positive Growth Expected in 3D Printing Materials

The 3D printing materials market is expected to grow from its present annual value of $310 million to $1.4 billion by 2019. That is substantial growth, and represents a large opportunity for independent manufacturers. Independent manufacturers already have a large market share within the 3D printing materials sector. The types of plastics used in 3D printing continues to evolve, while three main filament materials currently used are nylon, ABS, and PLA (Source: https://www.3dprinterworld.com/article/14-billion-plastics-sales-from-3d-printing-2019). Expected market share for other plastics is projected to rise over the next few years as well with new materials such as wood filament and polypropylene entering the market as demand grows for specialized 3D printing uses. (Source: https://gizmodorks.com/blog/3d-printer-filament-types/)

The 3D Printing Impact on the Medical Community

In the medical community, 3D printing has huge potential. Exciting new research and prototypes are under development as scientists are close to having the ability to create fully working human organs straight from a bio-printer. This would dramatically cut down on deaths caused by the backlog of individuals waiting for kidney transplants. The pancreatic organ is also potentially printable, which would virtually eliminate diabetes if the concept can be brought to reality (Source: https://thinkprogress.org/health/2013/05/23/2054281/promising-uses-3d-printing-medicine/). Skin grafting is another projected use for 3D printers in the medical community, with bio-printed skin forecasted to be achievable at a very small fraction of the cost of traditional skin-grafting. Prosthetic limbs and dental work are additional applications at the forefront of the 3D printer’s future impact on the medical community.

How 3D Printing is Moving into Aerospace

In the aerospace industry, parts produced via 3D printer have found their way into the Juno spacecraft, which is currently in route to Jupiter (Source: https://www.washingtonpost.com/business/capitalbusiness/why-the-aerospace-industry-is-investing-in-3-d-printing/2014/06/12/b7cfbf96-e02f-11e3-8dcc-d6b7fede081a_story.html). 3D printed parts are also being used on one type of drone used by the Navy. Engineers are planning to use 3D printed parts in a new fighter jet as well. While the parts aren’t currently used for load-bearing or mass-produced purposes, this could change quickly. It seems that although 3D printed parts are mostly used for models, the technology will soon be mature enough to use in everyday production.

The 3D Printing Business Revolution

Lastly, 3D printing is poised to shake things up quite a bit in the business community. The entire manufacturing supply chain stands to experience a paradigm shift as 3D printing emerges into the mainstream (https://www.theguardian.com/sustainable-business/2014/nov/25/how-3d-printing-is-set-to-shake-up-manufacturing-supply-chains). All plastic parts that are currently made in one location and shipped to local manufacturing plants could be theoretically printed on-site. This would lessen logistical and transportation requirements and drastically reduce costs. Additionally, many plastic toys and components that are one-piece could be printed at home, and the market would change from plastic pieces purchased in-store or online to downloadable blueprints designed for at-home printing. Recycling could be impacted as well, with local 3D print-shops reclaiming plastics and putting them right back into use as something else.

The impact of 3D printing is only just beginning to be felt across a variety of industries as the technology is still an emerging one. However, like James Watt’s steam engine in 1775 or Thomas Edison’s incandescent light bulb in 1879, 3D printing may change the way people live and interact with technology for centuries to come.