Table of Contents

Key Takeaways:

- Smooth flow pumps provide consistent, pulse-free fluid movement, ensuring precise dosing and accurate measurements in various applications.

- These pumps offer versatility by handling a wide range of fluids, from highly viscous to corrosive liquids, making them suitable for diverse industries.

- With their robust construction and efficient design, smooth flow pumps enhance operational performance, reduce downtime, and lower maintenance costs.

Have you ever struggled with inconsistent flow rates or pulsating pressure in your liquid handling applications? If so, you’re not alone. Traditional pumps can introduce unwanted fluctuations, disrupting processes and impacting product quality. Smooth flow pumps hold the answer, a cutting-edge technology purposefully engineered to unlock the secrets of seamless liquid handling.

Grasping the unique strengths of smooth flow pumps puts you in the driver’s seat. With this knowledge, you can make confident decisions that rev up operational performance while sending downtime issues to the scrapheap. Read on as this article uncovers the benefits of smooth flow pumps and explains why they are becoming an indispensable component in modern liquid transfer systems.

Types Of Smooth Flow Pumps

Smooth flow pumps are essential for a variety of applications where consistent and precise liquid handling is crucial. There are several types of smooth flow pumps, each crafted to meet specific needs and handle different kinds of fluids. Here are the main types:

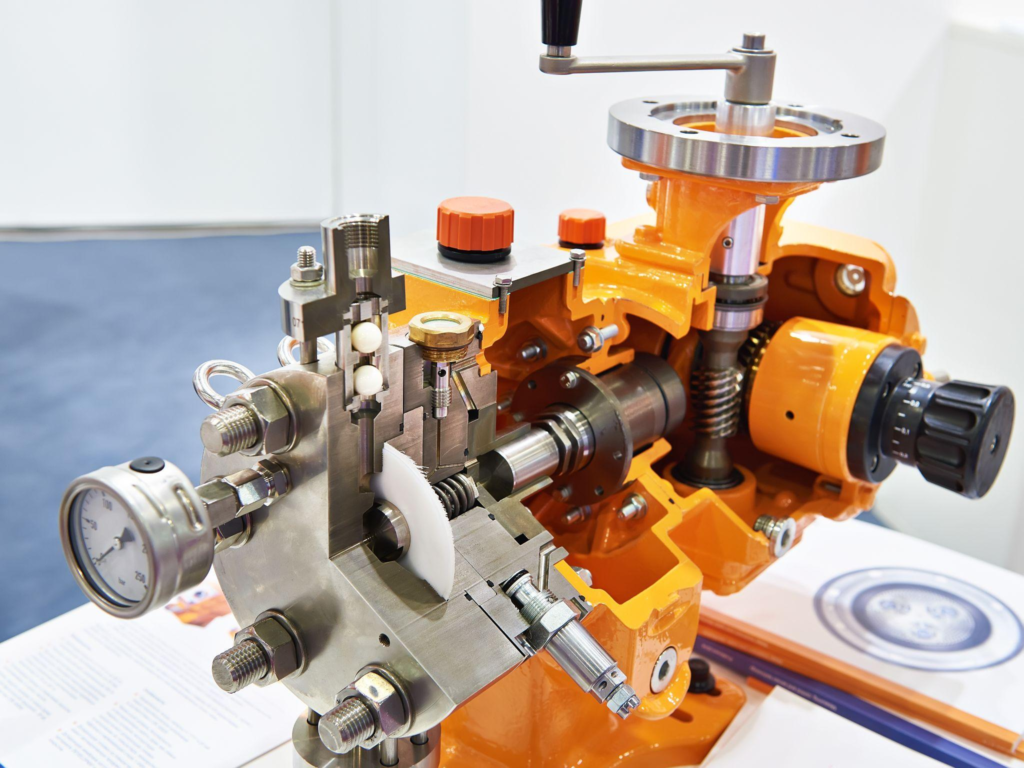

Diaphragm Pumps

Smooth flow pumps are well-equipped to transfer viscous or abrasive fluids, renowned for their durability and capability to withstand high pressures. Their robust design allows for efficient handling of demanding fluid media across various industrial applications. Manufacturers like KNF USA engineer diaphragm pumps that deliver reliable and versatile performance, ensuring consistent operation under stringent conditions.

Peristaltic Pumps

Peristaltic pumps use a rotating mechanism to compress and move fluid through a flexible tube. This type of pump is ideal for handling sterile or corrosive fluids because the fluid only contacts the tubing, reducing the risk of contamination.

Gear Pumps

Gear pumps consist of two or more gears that mesh to move fluid. These pumps are excellent for high-viscosity fluids and provide a steady, pulse-free flow. They are commonly used in applications requiring precise dosing and metering.

Piston Pumps

Piston pumps use a reciprocating piston mechanism to move fluid. These powerhouses can crank up the pressure to soaring levels, making them go-to heroes for applications demanding pinpoint precision over flow rates, such as in hydraulic systems and chemical processing.

Each type of smooth flow pump offers unique advantages and is suited for different applications. By understanding the characteristics and benefits of each type, you can select the right pump for your specific liquid handling needs.

Benefits Of Smooth Flow Pumps

Smooth flow pumps are crafted to deliver a steady, uninterrupted stream of fluid – a crucial necessity for countless industrial and commercial operations. Continue reading and explore the advantages that these pumps offer:

Precision And Accuracy

Smooth flow pumps excel in delivering a steady flow rate with minimal pulsation, making them indispensable for processes that demand precise dosing and accurate measurements. With their knack for maintaining a steady flow rate, these pumps deliver the precise fluid volume every single time. This consistency is critical in industries like pharmaceuticals and food production, where even the slightest deviation could compromise product quality.

Versatility

One of the standout features of smooth flow pumps is their versatility. They can handle a broad spectrum of fluids, including those highly viscous, corrosive, or sensitive to shear. This adaptability makes them suitable for a diverse range of industries, from chemical processing and biotechnology to water treatment and cosmetics. Effortlessly tackling all kinds of fluids without skipping a beat, these pumps offer unmatched flexibility for your operational processes. Complex liquid blends pose no problem for their versatile performance.

Efficiency

Efficiency is a critical factor in any industrial process, and smooth flow pumps deliver on this front by operating with high efficiency. Their design minimizes friction and wear, resulting in lower energy consumption and reduced operational costs. What’s more, their energy-efficient operation means less excess heat, which can be beneficial in temperature-sensitive applications. This high level of efficiency not only lowers energy bills but also contributes to a smaller environmental footprint, aligning with sustainability goals.

Durability And Reliability

Smooth flow pumps are built with robust materials and engineered to withstand demanding operating conditions. Their construction ensures minimal wear and tear, leading to long-lasting performance and reliability. This durability means that the pumps can maintain consistent performance over extended periods, reducing the frequency of replacements and lowering maintenance costs. In industries where downtime can be costly, the reliability of smooth flow pumps is a significant advantage, ensuring continuous and uninterrupted operation.

Safety

Safety is paramount in operations involving hazardous or sensitive materials, and smooth flow pumps enhance safety through their design. These pumps are designed with safety in mind. Their leak-proof construction and delicate handling of liquids drastically lower the chances of hazardous spills or exposure. Their sealed construction acts as a shield against contamination – an essential safeguard in industries like pharmaceuticals and food production, where absolute purity reigns supreme.

Reduced Maintenance

One of the practical advantages of smooth flow pumps is their reduced maintenance requirements. With fewer moving parts compared to traditional pumps, smooth flow pumps are easier to maintain and less prone to mechanical failure. This simplicity in design leads to lower maintenance costs and reduces the frequency of downtime for repairs. Keeping these pumps in top shape is a breeze thanks to their straightforward maintenance needs. Quick inspections and servicing ensure optimal performance and help extend their lifespans.

Improved Process Control

Smooth flow pumps deliver a steady, consistent stream, giving you precise command over your processes. This unwavering flow boosts efficiency and reliability across the entire production line, keeping operations running smoothly. In applications where precise flow control is critical, such as in chemical dosing or pharmaceutical manufacturing, smooth flow pumps provide the necessary accuracy to maintain strict process parameters.

Conclusion

Smooth flow pumps are more than just pumps – they’re the future of liquid handling. Their ability to deliver a smooth, precise, and reliable flow makes them an essential tool for a wide range of industries. If you’re looking to revolutionize your liquid handling processes and achieve unparalleled results, embrace the future – embrace Smooth flow pumps.