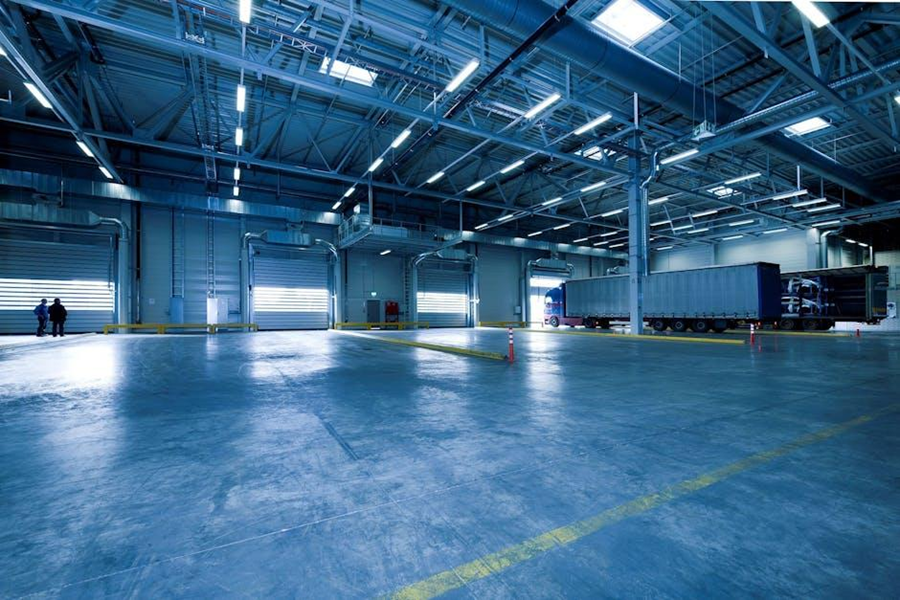

Modern enterprises value efficiency, but overuse has diminished it. What matters now is beating the clock and outwitting chaos. Warehouses needed heavy boots, sharp eyes, and luck. Not anymore. A race with split seconds and razor-thin margins has begun. Rapid technological advancement brings both opportunities and challenges. The correct strategies affect labour costs, accuracy, and customer satisfaction. If you make a mistake, someone else will grab your earnings. Four methods dominate this new landscape. Each has risks and rewards.

Table of Contents

1. Robotics for Repetitive Tasks

Some jobs deplete people. Picking boxes from rows and moving goods is uninspiring. This is where warehouse automation shines. Robots work without breaks or overtime, while humans focus on inventory planning and process development. Better than humans, machines choose, pack, and sort. Customers call it swift and accurate shipping, while skeptics term it impersonal or chilly. It is no longer considered science fiction. It’s normal for warehouses to try to compete in congested markets.

2. Smart Inventory Management

Data don’t lie, and products pile up because some warehouses still gamble with guessing rather than knowing what sits on every shelf right now. Smart inventory tools provide instant visibility (think sensors that automatically count stock or software that predicts when supplies are running low). No more frantic searching for missing goods or backorders blamed on “system errors.” Wasted space shrinks rapidly when inventory finds its proper home based on real-time demand, rather than outdated forecasts from the previous quarter. The smartest operations link inventory management straight into sales systems so reordering isn’t an afterthought but a natural flow.

3. Mobile Devices Empower Workers

Old antiques like clipboards belong in history books, like rotary phones and floppy discs. Since paper trails are tedious, today’s workers use mobile scanners and rugged tablets to expedite operations and minimize confusion. Without waiting for updates, floor personnel can track shipments promptly and coordinate across departments using mobile devices. Touch-based data capture boosts efficiency and minimises errors by verifying everything twice before slowing down.

4. Automated Guided Vehicles Take Over Transport

Previously, forklifts roaring past pedestrians would often cause incidents involving a single distracted worker. Transporting items between loading docks, storage racks, and assembly lines securely, without the need for human involvement, is the responsibility of automated guided vehicles, often referred to as AGVs. AGVs will travel through warehouse grids at expected speeds without incident, day after day, if you set a path for them and then observe them in action. Increasing the number of shipments per hour does not result in increased traffic congestion or more risks for coworkers who check in both directions before crossing aisles.

Conclusion

Trying to be flawless wastes energy. The lesson is to favor growth over stagnation, especially when technology allows advancement now rather than next year. Competitors may be ahead by now. Business performance hinges more than ever on getting these strategies running smoothly together since no single fix covers all weaknesses lurking beneath those high ceilings and endless rows of pallets waiting their turn to move out the door at the speed customers expect today, not tomorrow.

Image attributed to Pexels.com